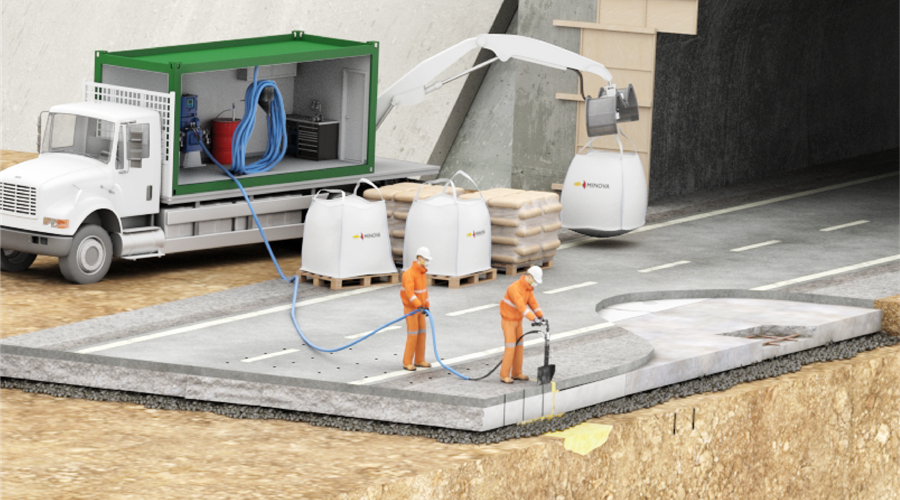

Road maintenance

Road maintenance

Minova resins provide innovative, cost effective and time efficient solutions to support highways. Highly specialized resins displace any trapped ground water and fill all voids in the sub-formation, thus stabilizing the pavement.

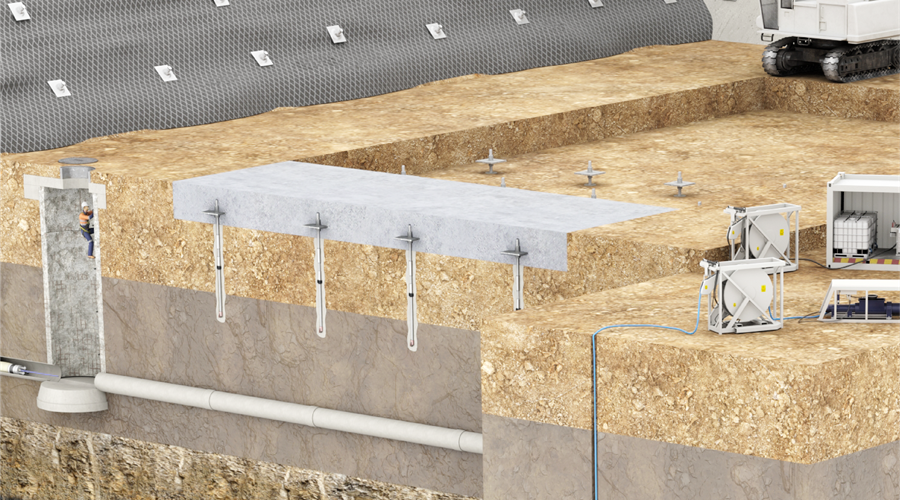

Micropile foundations

Micropile foundations

Our self-drilling anchors provide quick rates of installation by combining drilling, insertion and grouting in one single operation, securing your deeper foundation.

Slope & wall ground engineering

Slope & wall ground engineering

Our full package solutions comprising soil nails, rock bolts, plates and mesh, secures your ground, maintains safety and protects your asset.

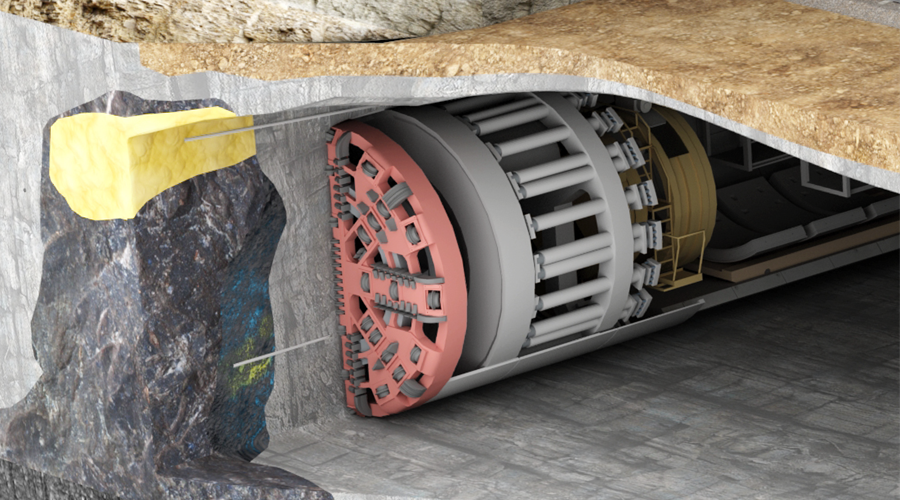

Tunnel maintenance

Tunnel maintenance

Choose from our resins, grouts and steel portfolio for fast and efficient crack injection sealing, void/annulus filling and water stopping solutions to keep your assets safe regardless of tunnel type, location or size.

Sewer repair

Sewer repair

With excellent adhesion and high chemical and thermal resistance, our liners and resins ensure pipeline integrity and stop leakages.

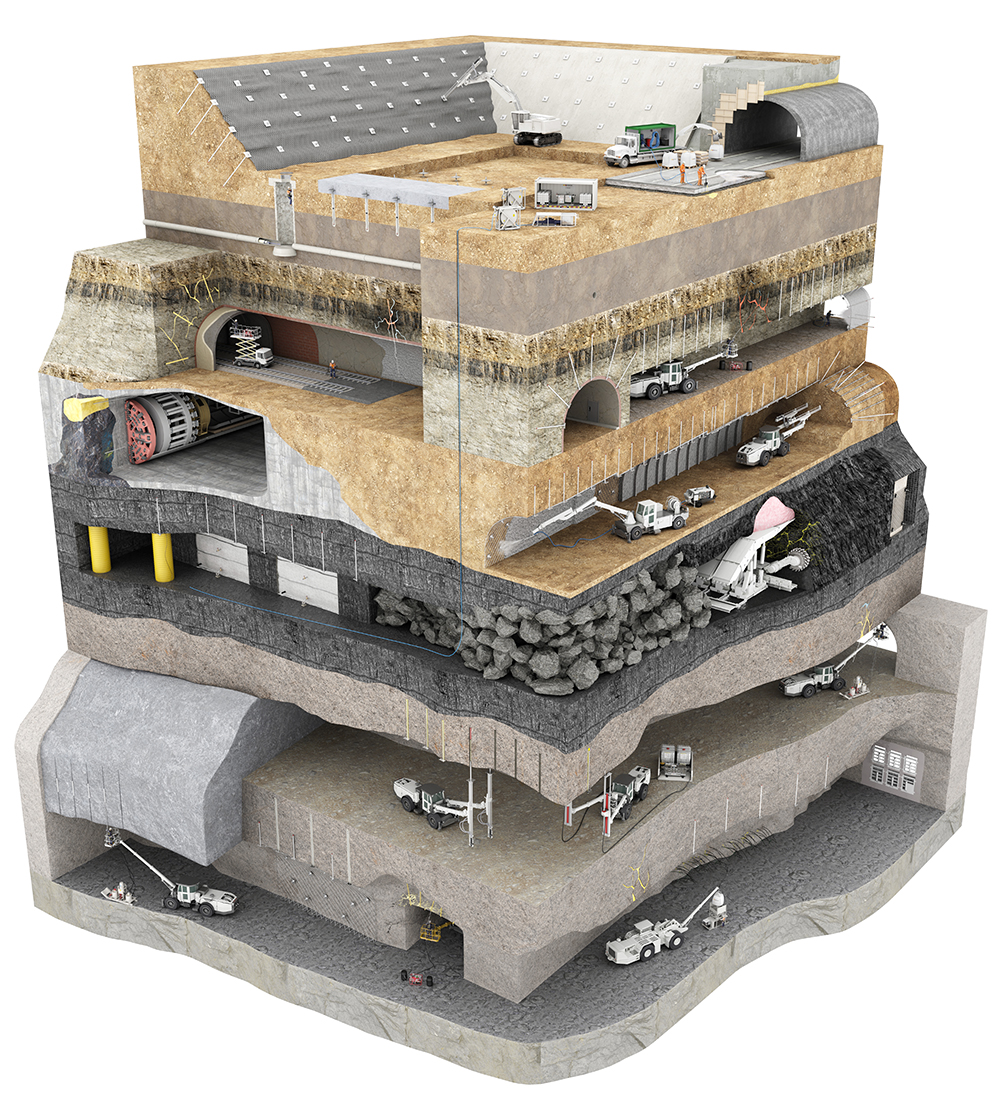

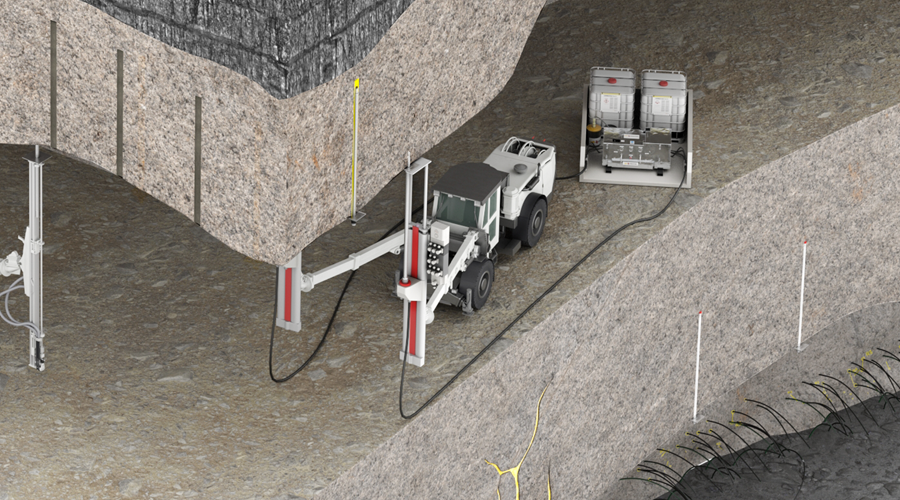

Surface to underground delivery

Surface to underground delivery

Minova pump systems can deliver our grout and chemical product solutions from the surface to underground, maximising your safety, increasing efficiency and reducing your underground labour.

Ground consolidation and stabilisation

Ground consolidation and stabilisation

We have multiple resin and grout solutions for temporary or lifetime support of cracks and voids in tunnel construction and lining, tunnel boring machine passage and/or longwall operations, that enable your project to proceed with efficiency and safety.

Water control

Water control

Our extensive range of injectable products and systems are used for water control in both above and below ground environments, providing future leak security whilst minimising downtime.

Cavity filling

Cavity filling

Choose from our range of quick-setting resins and grouts that provide immediate support to multiple rock surfaces underground, for rapid and safe progress.

Ground Control

Ground Control

From our wide-ranging portfolio of anchors with supporting resins and grouts, our leading solutions support your ground in any environment, maintaining your confidence in ground security.

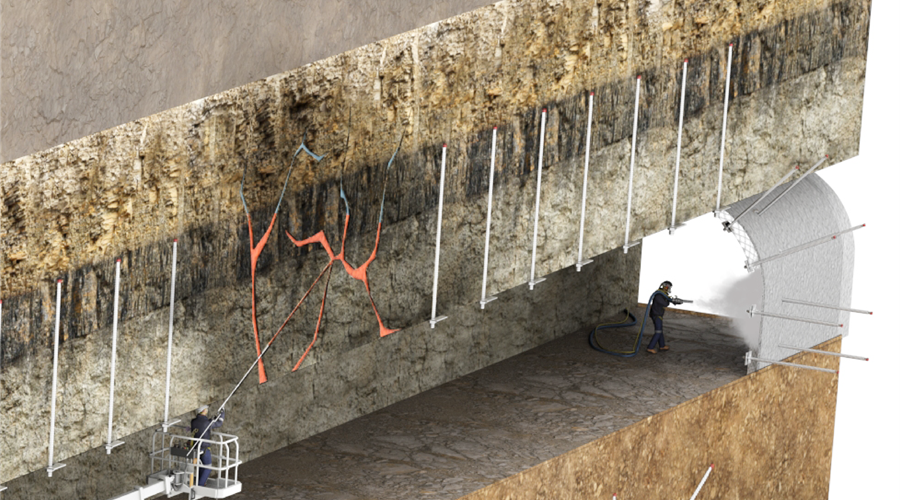

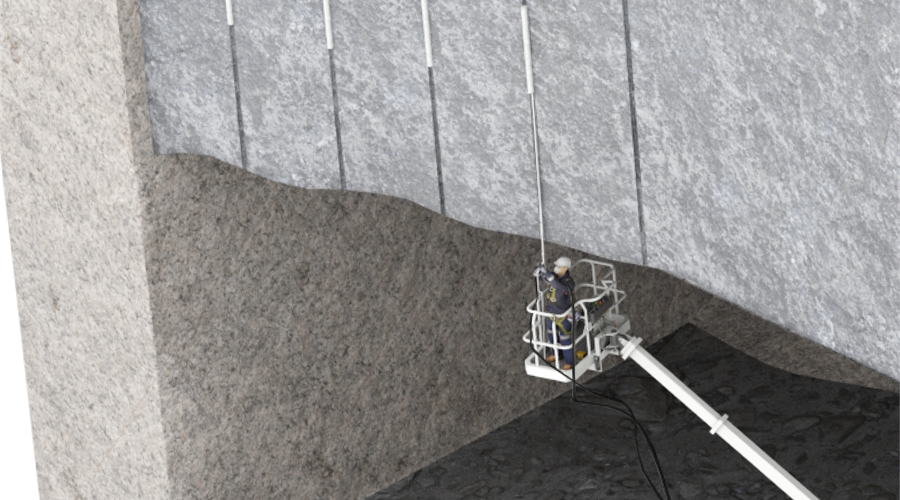

Surface support

Surface support

We supply a broad range of wet and dry sprayed products, which function as either structural or waterproofing membranes and linings, preventing migration of water or rock face movement, giving immediate stability in challenging ground conditions.

Standing roof support

Standing roof support

We provide systems to pump grout into crib bags that offer substantial benefits in terms of speed and ease of installation to maintain roof stability. Choose either surface to underground delivery or in-situ application.

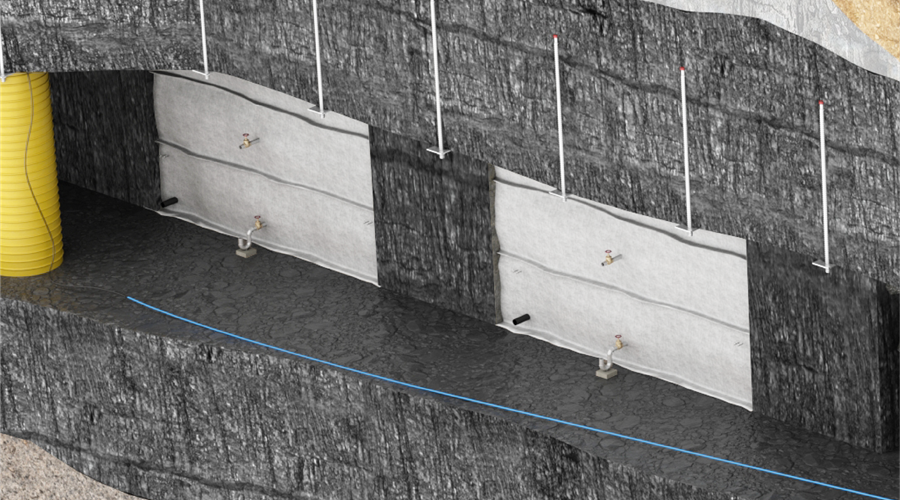

Seals & Barriers

Seals & Barriers

Our high performing seals, plugs and stoppings can be designed to fit the strata conditions and roadway dimensions of mines to provide solutions for large-scale air, gas and water control, to ensure maximum safety and access underground.

Pre-driven roadway pillars

Pre-driven roadway pillars

For the safe and efficient relocation of longwalls, we provide pre-driven road support incorporating cuttable grout pillars and a grout and formwork delivery system, which enables key productivity and safety improvements during longwall recovery.

Ultimate stemming

Ultimate stemming

Our uphole stemming technology comprises non-shrinking, quick curing, low temperature, and high strength grouts, that combined with a delivery system and sealing process allows charging and stemming to be completed quicker.

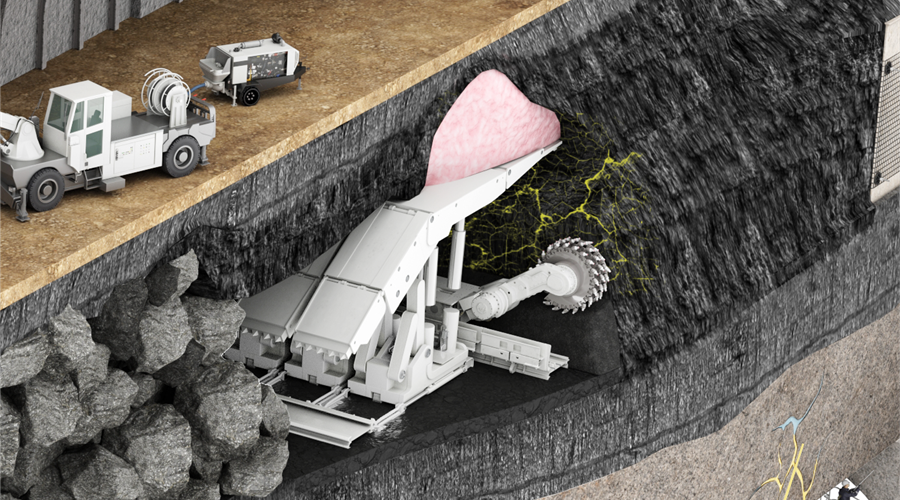

Ore recovery optimisation

Ore recovery optimisation

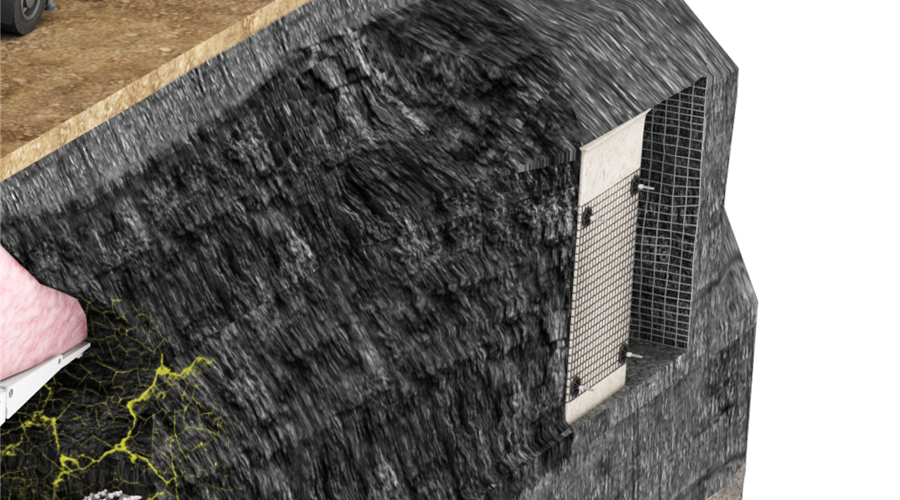

Our solutions can maximise the extraction of previously sterilised ore resources, by stabilising broken material in the stope.

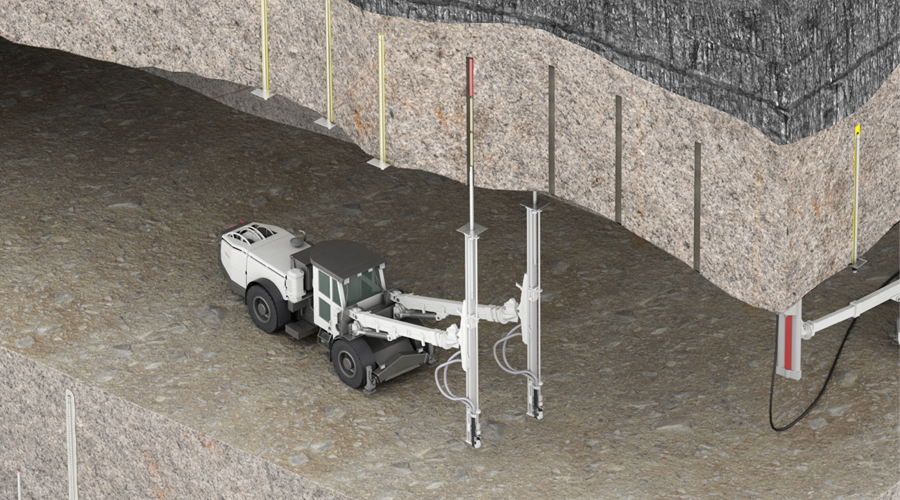

UniPass single pass bolting technologies

UniPass single pass bolting technologies

Increased development productivity through OEM and retrofit bolting solutions. UniPass bolting combines our static, yielding and dynamic hollow bolts and CarboThix bulk resins engineered to suit the most demanding requirements of underground mining and tunnelling.

Ventilation

Ventilation

Maximise the time available to underground operators by allowing them to work in a controlled, ventilated environment. Our range of airflow regulators and ventilation blinds help provide clean air, supporting the health and safety of your team.